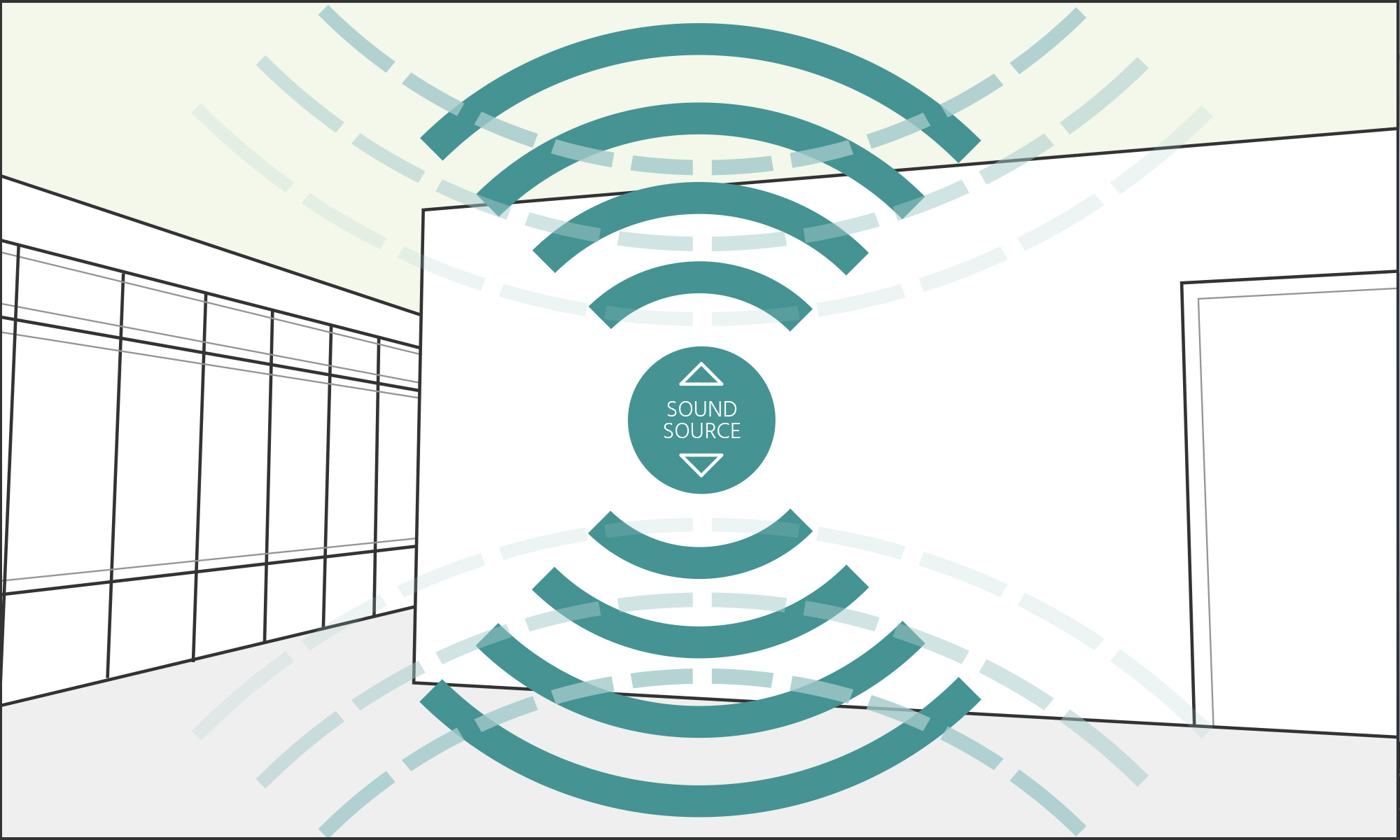

Reverberation is very recognizable in a big space, especially when it’s excessive. People refer to such a room as “echoey” or simply too noisy. Sounds that are introduced into the space (impulse) seem to linger for a little while before diminishing to nothing. It’s a characteristic measured in seconds and termed Reverberation Time.

When sounds linger in a space the subsequent sounds that are introduced, as in speech, are partially covered over by the previous sounds and not as easily understood. This is sometimes desirable, such as for music that is based in harmony, so spaces for different types of music have various recommended reverberation times. Spaces for acoustical comfort and for speech should have low reverberation times, usually 1.0 seconds or less. Lowering reverberation time reduces reverberant noise levels.

The concept of reverberation time was developed by Wallace Sabine in 1898, for which he is considered to be the Father of Architectural Acoustics. He discovered a simple relationship where the time that sound lingers in a space (actually a drop of 60 dBA from the impulse to being unheard) is directly proportional to the cubic volume of the space and inversely proportional to the amount of sound absorption in the space. The amount of sound absorption is the product of the surface area (S) of each type of material in the space and that material’s ability to absorb sound at various frequencies known as the absorption coefficient (a). The average of the coefficients in the middle frequencies yields a single-number value called the Noise Reduction Coefficient (NRC). To honor Wally, the amount of sound absorption is measured in sabins although it’s just square feet. STC honors Wally by naming our panels Hi-Sabin.

All materials absorb, reflect or transmit sound energy, each at different proportional amounts. Sound isn’t really absorbed like water in a sponge. In porous materials air molecules near the surface are knocked into open crevices in the surface of the material by the moving air molecules of sound waves. Friction with the walls of the crevices lowers the intensity of the sound power in the wave (loudness). Also, once the air molecules return from these crevices into the space they do so at different times than neighboring molecules because of the differing amounts of friction each encountered. This destroys the pattern of air pressure variations in the wave, which is really what sound is. The melamine-based foam of STC Hi-SabinTM Panels has an open cell structure (lots of very small crevices) and is extremely efficient in the process of sound absorption. Most foams are closed cell and don’t absorb sound, such as Styrofoam.

The sound absorption process works by exposing the material to the air molecules that comprise the sound wave. By furring or suspending the panel and spacing them apart there is more opportunity for the sound to be absorbed because the back and sides of the panel are exposed to the sound wave. The absorption coefficient is calculated by considering the ratio of the amount of sound absorbed compared to the amount incident on the front surface area of the panel.

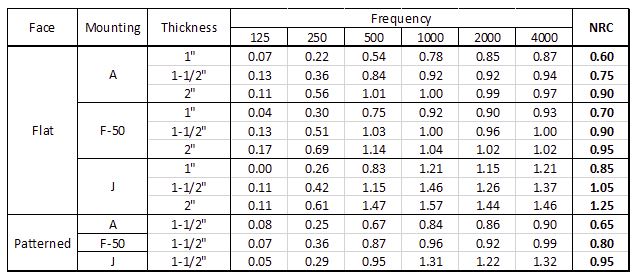

Since sound is also absorbed on the back and sides of the panel these coefficient values can rise above 1.0 – surprising because that means more than 100% of the sound energy incident on the panel is absorbed, a seemingly impossible physical task unless the measurement procedure is understood. (We really do give 110%).

The calculation of the amount of sound absorption needed in a space is fairly simple. Figure the number of cubic feet in the space (V), divide by the desired reverberation time in seconds (T), and multiply by 0.05 (a constant in seconds/foot related to the volume measurement in cubic feet and the 60-dBA drop figured by Sabine). This gives the number of sabins required (SSa) to get the desired reverberation time. Figure the number of sabins (square feet x NRC) supplied by each of the other materials in the space on the walls and floor that are exposed to the sound. The difference between the total sabins required and the sabins from other materials is the number of sabins needed to be provided by the panels. Divide that value (required sabins to be supplied by the panels) by the NRC of the Hi-SabinTM Panels selected and the total square feet area of panels required is obtained.

Values in the chart above for Type “A” Mounting are for direct-adhered panels butted together. Type “F-50” Mounting values are for panels mounted on 2-inch-high standoffs and butted together. Type “J” Mounting values are for panels mounted on standoffs and spaced apart in a pattern.

Controlling reverberation time only controls the reverberant sound energy in a space. People will still hear the sound that comes directly from a source in the same space, such as from other people in the vicinity that they may not want to hear. The direct sound level will only diminish with distance from the source. For that reason, the density (area per occupant) of patrons in a restaurant, for example, is just as important a consideration as reverberation time for achieving acoustical comfort.